POWAR anti-vibration insulating base-plates

The base-plates of POWAR type present a new original solution for anti-vibration insulation of the machine tools and they are distinguished by many advantages as compared with the well-known foreign and domestic designs of such a type.

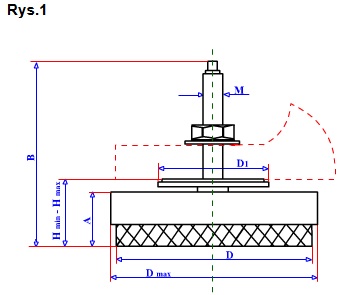

The base-plates are manufactured in three sizes: POWAR 110, POWAR 140, POWAR 170 (Fig-1 and Tab.-1).

Table.1

| Technical data | Unit | Type of base-plate | ||

| POWAR 170 | POWAR 140 | POWAR 110 | ||

| D Dmax D1 Hmin* Hmax* A * B M Total weight of the base-plate Rated load Maximum load Stabilisation of the frequency of free vibrations Stabilisation of the frequency in the 0 range | mm mm mm mm mm mm mm mm Kg Kg Kg Hz Hz | 170 190 77 75 96 60 227 24x1,5 ~6,0 1200 1500 11±1 600 : 1300 | 140 158 77 63 80 50 198 20x1,5 ~3,6 800 1000 15±1 400 : 900 | 110 124 57 50 64 40 165 16x1,5 ~2,5 500 700 11±1 300 : 700 |

| *Dimensions of the non-loaded base-plate | ||||

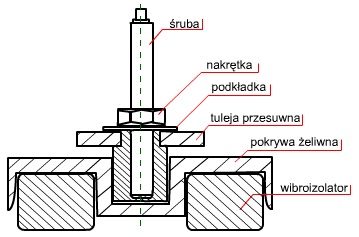

The base-plates of POWAR type have simple construction and are composed of six parts: an anti-vibration insulating element, a cover, a threaded sleeve with a flange, a bolt, a washer under the nut and a nut.

All the parts are replaceable. The POWAR base-plates act as active and passive anti-vibration insulators, i.e., the plates insulate the base from vibrations when the source of vibration is a machine tool and they also insulate the machine tool from the vibrations occurring on the base.

Advantages of POWAR base-plates

The base-plates have markedly non-linear static characteristic, thanks to which they act extremely effectively as anti-vibration insulators, especially in the case of disturbances and vibrations such as impacts, shocks etc.

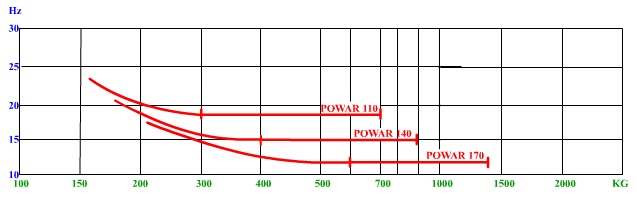

Due to their special construction, the base-plates are characterised by stability of the frequency of free vibrations versus static loading in a wide range of variation of such loading (Fig. 2). Such a property of the POWAR base-plates distinguishes them favourably from among domestic and foreign solutions of this type of construction. Due to this fact, when on the base there occur vibrations generated by the forces of percussive nature (or similar), the frequency of the vibrations, which may be transferred to the machine tool, is identical in all the supports irrespective of the static loading of the base-plate installed in a given point of support.

Stabilisation of the frequency of free vibrations causes that the changes of loads have not any influence on the dynamic properties of the base-plates and the accurate calculation of the loads on individual base-plates (in the places of installing the base-plates under the machines) is needless.

It is enough to estimate a supposed range of possible loads for a given point of support (of a given support) – accurate and detailed calculations are not necessary. This facilitates selection of the size of a base-plate and reduces the time of assembly.

The low stabilised frequency of free vibrations provides an additional advantage - it has a favourable influence on the quality of the worked surfaces and allows correct designing and constructing of the machine tools.

The base-plates are chemical resistant, i.e., they are resistant to the action of lubricants, oils, hydraulic and cooling fluids and so on; the basic advantage is that the vibrating element made of rubber does not change its static or dynamic properties and characteristics.

Fig. 2 Frequency of free vibrations versus static loading

Simple construction of the base-plates and replaceability of the anti-vibration insulating elements facilitates the assembly and operation. The regulated height of the base-plates enables setting the machine tools on the uneven base.

The foundation is needless; the base, on which the machine tool is placed, should be of concrete, but this condition is not unquestionably necessary. The base-plates can be installed even on the base initially hardened; the surface, on which the base-plates are set, must be free of set-offs, cleaned off chips and so on, and its gradient must not exceed 4º. The adherence of the base-plates to the base is very good.

Range of application of POWAR 110, 140, 170 base-plates

The base-plates are designed for placing under the milling machines or other machine tools for medium-accurate working (lathes, drillers, automatic machines and so on). The base-plates can be successfully used for other types of the machines, after checking their usability considering the requirements laid down by a user for operation of such machines. Generally, the POWAR base-plates should not be used under the machines with a strong percussive action or with considerable horizontal forces that occur during the operation of the machine tools. The POWAR base-plates can be used only under the machine tools with the sufficiently rigid bodies, which do not require additional stiffening by their fixing to the foundations. In the case of the use of base-plates under the machine tools with a long bed – the distortions of the body should be checked. In the case of the use of POWAR base-plates under the machines with a high value of the ratio of a height to the width of a machine – the stability of the machine should be checked.

Principle of selection of base-plates

Under a given machine, there should be used only the POWAR base-plates of one size – selected according to the loads occurring on the support.

Example:

If the biggest static loading on the support (a place of supporting) loaded most of all supports of the machine tool is some 800 kg (rough estimation), then there should be used the POWAR 140 base-plate (see Fig. 2) on all points of support of the machine tool.

The solution of the POWAR base-plates is protected by the patents No 81374 and 91155